WaterTech Reverse Osmosis Water Purifiers

- Drinking water which one gets from municipal supplies or ground-well are getting deteriorated and are containing lot of dissolved impurities. You have been purifying this water through UV/Electronic Boiling based purifiers and thinking that purified water is purest and totally safe. Have you checked for the following:

Electronic Boiling based water purifiers do not remove soluble impurities like salts, pesticides, heavy metals and harmful chemicals which can cause serious diseases. - Electronic Boiling based water purifiers only deactivates bacteria and viruses and the dead ones remain in the purified water. There are chances of getting them re-activated on long storage/ increased temperature conditions.

- The answer is clear that outdated Electronic Boiling based water purifiers cannot cater to the presently available drinking water from municipalities or ground wells.

- Thanks to revolutionary Water Tech Systems R-O (Reverse Osmosis) Water Purifiers, you can now purify tap water or even ground well water to absolutely safe and pure, sweet and tastiest drinking water. Watertech Systems R-O Water Purifiers besides removing insoluble impurities also remove soluble impurities like salts and heavy metals.

Check for the following advantages of Water Tech Systems R-O System:

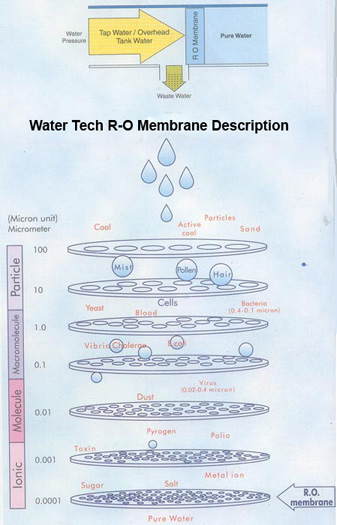

- Water Tech Systems R-O Water Purifiers remove all bacteria & viruses (Dead / Alive) because of filtration through R-O Membrane whose pore size is below 0.0001 micron.

- Removes even soluble impurities like pesticides, fluorides, heavy metals & undesirable salts.

Enhances taste of water & makes it sweet.

Water Tech Systems R-O Water Purification System.

- Reverse Osmosis is a process wherein water is forced through a semi-permeable Membrane by applying strong pressure, thereby allowing only fine water molecules to pass through it. All contaminants such as bacteria, viruses, herbicides, heavy metals and chemical poisons are removed. With added special features, pure water is then collected in a container and dirty water with impurities is discharged separately.

- The diameter is less than 0.0001 micron (which is 500,000 times less than the diameter of our hair.)

- R-O Membrane is able to filter harmful substances like suspended particles, viruses, bacteria, heavy metals etc.

RO Process

Water under pressure is passed through membrane having pore diameter of 0.0001 micron that removes than 90% of dissolved salts and only allows required residual minerals and pure water molecules. Purified water is collected for use in a storage tank and water impurities are flushed through reject port. Reverse osmosis will not remove all contaminants from water as dissolved gases such as dissolved oxygen and carbon dioxide not being removed. But reverse osmosis can be very effective at removing other products such as trihalomethanes (THM’s), some pesticides, solvents and other volatile organic compounds (VOC’s). Reverse osmosis is a process that industry uses to clean water, whether for industrial process applications or to convert brackish water, to clean up waste water or to recover salts from industrial processes.

Softner

Many water supplies contain hardness minerals (calcium & magnesium). These minerals from scale and create problems in Hair Losses, Dishwashers, Coffee Makers. Softner Treat Hard Water Phisio Chemical Process Hard water passes through the resin column which is filled with a food grade cataion softing resin in the sodium form. This resin absorbs the calsium & magnesium ions from the hard water and release the sodium IONS into the water thus softing the water. When resin has completely exhasusted its sodium IONS. It needs to be recharged for 20 minutes with sodium salt short it is fed into the resin clumn & magnesium INOS and is charged with sodium IONS & finally gives soft water.

1. 3-CYCLE VALUE

Water Tech Systems uses a non corrosive single lever six way valve that operats in three cycles: softerning, brine draw and regeneration, and rinse. The water flow rates during these phases are controlled by built in flow restrictors. These valves are non corrosive and easy to operate.

2. PRESSURE VESSELS

user non-corrosive composit and Fiber Reinforced Polyster pressure vessels. These multi-wall light weight vessels are capable of withstanding pressures up to 10 Bar (150 psi)and being non-corrosive

are guaranteed to give longlasting performance.

3. SOFTERNER RESINS

Uses international quality polystyrene cationic resin suitable for softerning drinking water and water used for food processing. The prinipal characteristic of these resins and high exchange capacity and excellent regeneration efficiency.

4. SALT STRONG TANKS

The high capacity HDPE Salt Storage tanks allow extended periods between salt refills. These tanks are resistant to corrosion from salt, acids and alkalis.

5. BRINE WELL

A perforated HPED tube provides direct contact between the salt and the water to produced brine for regeneration.

6. BRINE DIRECTOR

The Brine Director injects a per-set quantity of soft water into the brine well to form brine for the next regeneration. The Dosing system allows the correct quantity for brine, in proportion to the quantity of the resin to be regenerated, to flow into the softerner on regeneration. The Brine Director is fitted with a safety device with a value and mechanical float to prevent any risk of the salt storage tank overflowing.

Softeners treat hard water by a physico-chemical process. When the valve is set on a service mode, hard water passes through the resin coloumn which in filled with a food grade cation softening resin in the sodium form. The resin absorbs the calcium and magnesium ions from the hard water and releases the sodium ions into the water, thus softening the water. When the resin has completely exhausted its sodium ions, it needs to be recharged and the valve is set to the regeneration mode for approx, 30 minutes. In the regeneration mode the sodium salt is fed into the resin coloumn and the resin releases the calcium and magnesium ions and is charged with sodium ions. Then the valve is set to the rinse mode which removes the brine remaining in the colomn until required quality is abtained.

ADVANTAGE

Softeners have numerous advantages over conventional softeners, namely:

• Corrosion resistant FRP Pressure vessel gives longlasting service.

• Corrosion resistant single lever six way valve made from engineering plastics is easy to operate.

• Fittings, pipings and accessories made from corrosion free PVC materials for long service.

• Efficient production of soft water.

• International quality resins suitable for drinking water systems release no substances that could alter the organoleptic

– Properties of treated water.

• High exchange capicity and excellent regeneration efficiency minimises salt consumption.